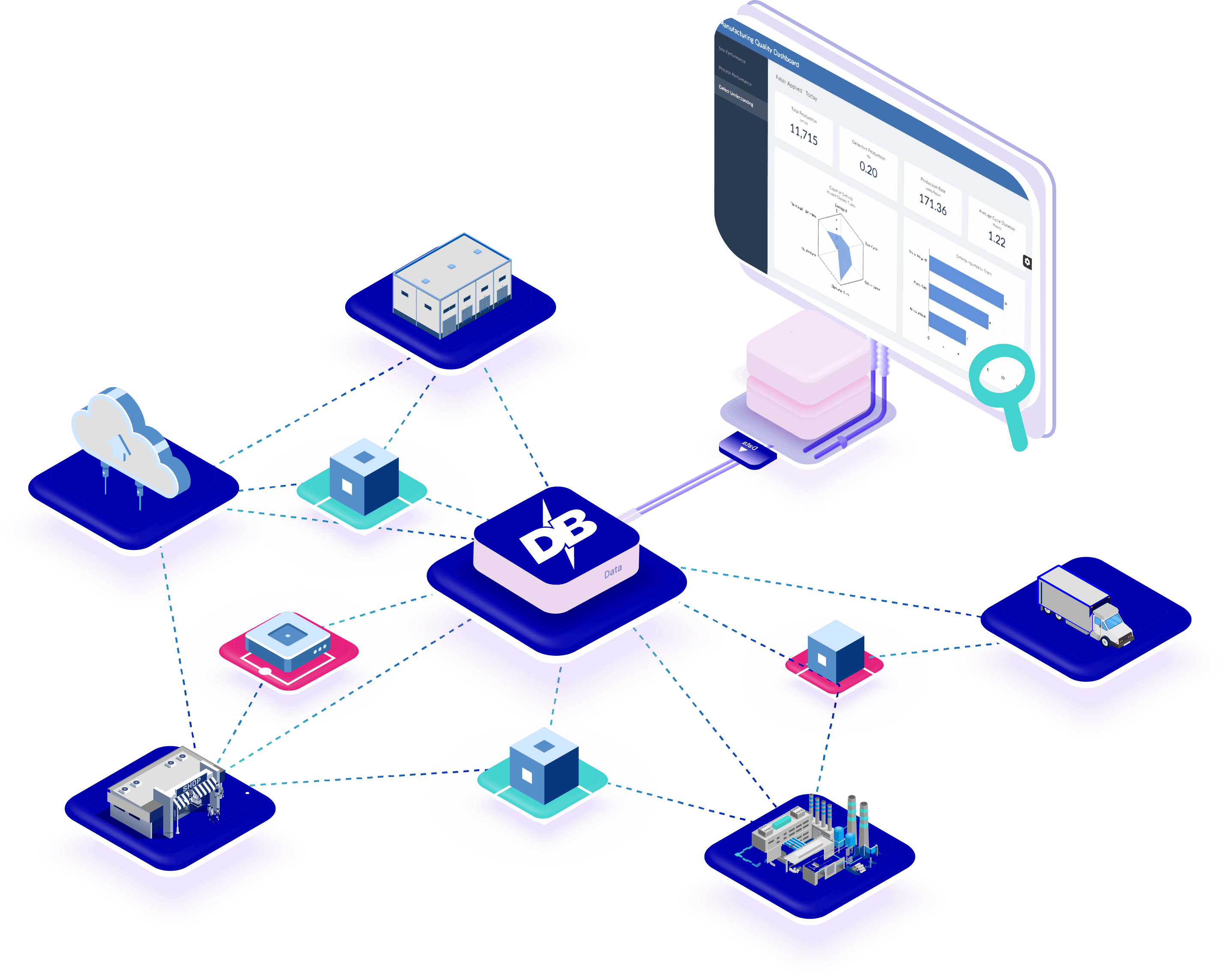

Manufacturing DataOps

Across manufacturing operations, the lack of ability for business users to explore data can inhibit efficiency, keeping them in the dark about key insights.

Schedule Demo

Embracing Industry 4.0

As Industry 4.0 within smart manufacturing becomes the standard, leaders who embrace a data-driven culture with their operations are poised for future growth and even higher operational efficiency.

Our Manufacturing DataOps solution contextualizes data with business terms, improves data accessibility for business users, and accelerates scalable advanced analytics. These improvements uphold Industry 4.0 standards lending way to data-driven organizations.

Bringing Pivotal Data into Focus

Don’t be among the 70% of manufacturers who haven’t made progress on their smart data driven manufacturing goals because of out-of-date data operations. Our solution bridges the gap between process, performance, and data. Here’s how:

Industrial Data Integration

Connect ERPs, MES, or any other systems surrounding your operations' with the only Data Management solution with Industrial domain intelligence built in. Our knowledge graph mDataOps software can help you monitor every part of your operations data in real-time while preserving your underlying architecture, helping you reduce manual data collection and analysis efforts by 80%.

Order Management

From the procurement process to the final shipment, our intelligent order management solution provides unmatched integration, tracking, and reporting efficiency.

In turn, your team gains visibility into what’s happening at each step of the operations, including order status, quality checks, equipment productivity & failure, distribution, and many more metrics.

Production Management

There's a reason why our mDataOps solution consistently enables manufacturers to improve their production schedule adherence by 20%.

Proactively maintain a comprehensive picture of your production operations from machinery, people, processes, to efficiency.

Overall Equipment Effectiveness

Throughout the manufacturing process, your machinery uptime, performance, and quality are integral components of your Overall Equipment Effectiveness (OEE) metrics. Bolster your management process through a robust command center that aggregates data from machines in real-time and predicts how it can impact your order.

By bringing data to light, integrating with your existing systems, and centralizing your oversight through dynamic dashboards, our OEE capability provides structure and superior planning capabilities.

Supply Chain Management

Our Supply Chain Management analytics capability enables you to assess your supplier network like never before while gaining holistic oversight surrounding exactly what's in your warehouses.

In turn, you can make vendor requests while alleviating uncertainty and fine-tuning your margin of error.

Total Quality Management

Today, 69% of manufacturers lack the structure and data aggregation from devices, partners and processes needed for quality operations.

By putting data driven quality checks within each step of the operations, our mDataOps solution can help you generate 20% higher quality yield. All the while, you can expect the highest accuracy in managing, measuring, and monitoring the process.

Request Your Complimentary Demo

If you’re ready to give your line workers and leaders the data-rich tools they need to thrive, our MES solution drives healthy KPIs across the board. Get started today with a complimentary demo.

Book Demo